News and events

Filter results

Search

All

About JASA

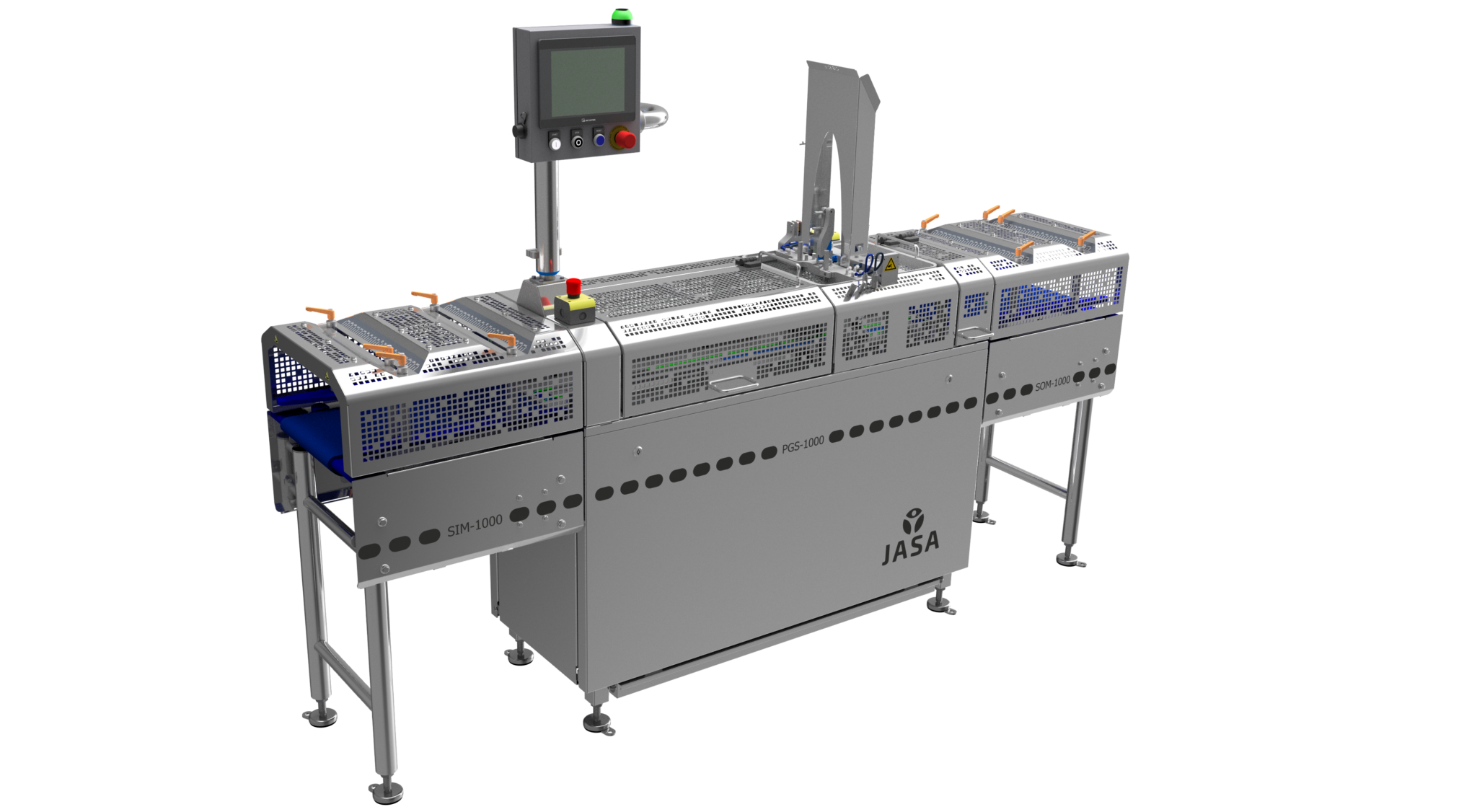

Packaging equipment

NXXT Packaging

A New Year, new opportunities, new dreams!

Read more

Paper packaging

About JASA

Packaging equipment

WOW! The NXXT Generation Vertical Packaging Machines

Read more

Sustainability

Client case

Paper packaging

Sustainability; Fenaco makes the difference

Read more

About JASA

Careers

Interview with Joost Breed

Read more

Subscribe to receive news and updates from JASA

About JASA

Leafy greens

The JASA packaging machine in America and Canada

Read more

Leafy greens

Packaging equipment

JASA's Rotary Filler: packaging leafy greens at lightning speed

Read more

Sustainability

Tomato packaging

Tomatoes: as diverse as wildly popular

Read more

No posts found

All

All

Can we help you?

.png)